Triphenyl bismuth /TPB best catalyst of the polymerization

- Packaging:

- Sealed, hard, cycloidal plastic case. Net weight 500g or 1000g per bottle. Packing can be adjusted according to the clients' requests.

- Supply Ability:

- 20 Ton/Tons per Month /customized service is available.

- Port:

- Dalian/Shanghai/China main port

Product Description

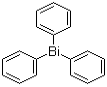

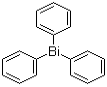

Product Description Triphenyl Bismuth Executive standard: GJB 5276-2003 CAS RN: 603-33-8 1. Physical and chemical properties: 1.1 Molecular formula: C18H15Bi 1.2 Molecular Weight: 440.3 1.3 Structure formula:

1.4 Solubility: Insoluble in water, but dissolved in anhydrous alcohol and n-heptane. 1.5 Stability and reactivity: Stable at normal temperature and pressures, but reacts with moisture, strong oxidant and strong ultraviolet light. 2. Technical indexes:

1.4 Solubility: Insoluble in water, but dissolved in anhydrous alcohol and n-heptane. 1.5 Stability and reactivity: Stable at normal temperature and pressures, but reacts with moisture, strong oxidant and strong ultraviolet light. 2. Technical indexes: | <Span style="line-height: 24px; font-family: 'Times New Roman'; color: #000000; font-size: 12pt;">Item | Index |

| Purity,% | ≥97.5 |

| Melting point,℃ | ≥77.0 |

| Bi content.% | 47.0-47.9 |

| Insoluble in acetone content,% | ≤0.10 |

| Mg content,% | ≤0.003 |

| Total halogen content(in Cl),% | ≤0.05 |

| Appearance | White or milky crystal, no visible impurities |

www.tanyunchem.com

www.tanyunchem.com

Contact us if you need more details on Polymerization. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tpb、Triphenyl Bismuth. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Polymerization. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tpb、Triphenyl Bismuth. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Military Chemical Series

Premium Related Products

Other Products

Hot Products

Metal Industry Usage PEG 600/polyethylene glycolFactory Bottom Price for for NR and SDR Factory Rubber Chemical CTP as Retarder Rubber Chemical PVIRubber Accelerator Pre-dispersed Masterbatch CBS-80Best price in South Africa for Industrial Production C7H5NaO2 CAS NO 532-32-1 BENZOIC ACID SODIUM SALTPotassium BichromateRICHON Rubber Chemical Antioxidant CAS No: 128-37-0 264 2,6-Di-terbutyl-4-methyl phenol Antioxidant BHT (264)Rubber Antioxidant TMQ(TQ)RICHON Free Samples Made In China Alibaba Online Shopping Industrial Chemical for Production Rubber accelerator ZEPC PXManufacturers Looking for Agents or Distributors Online Shopping RUBBER ACCELERATOR TE Powder CAS NO.20941-65-5 ACCELERATOR TDECZINC BORATERICHON Rubber Chemical Additive CAS NO 1333-86-4 Carbon Black Carbon nanotubes144060-53-7/FebuxostatAcrylic AcidHigh quality CE RICHON MLW-400 Capillary RheometerPOTASSIUM DICHROMATEFebuxostat API INTERMEDIATE